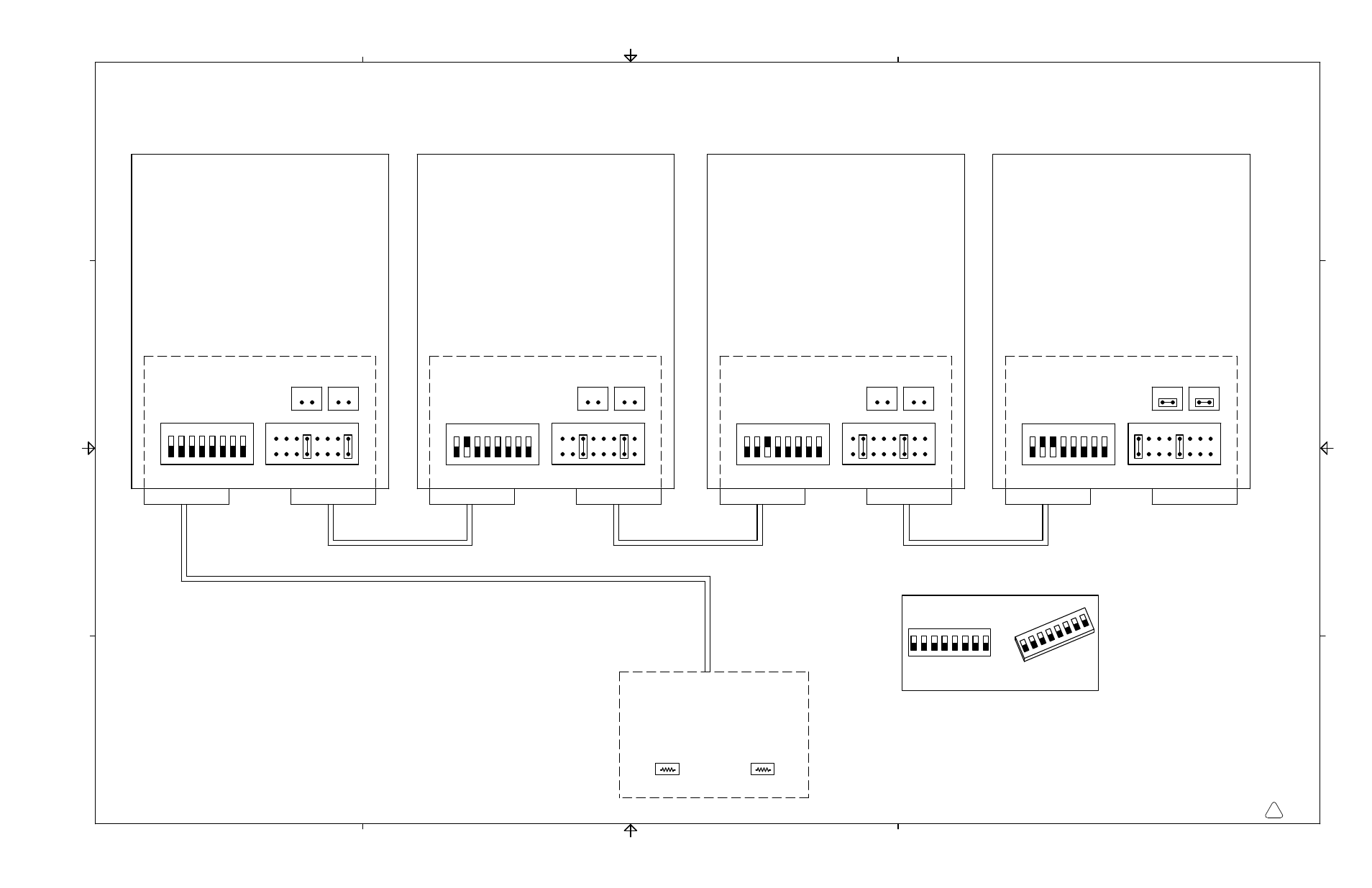

Optional multi-system interface, Elec sch:hpr400xd pwr sply w/auto, Hpr pac dry cutting system – Hypertherm HPR400XD Auto Gas Instrukcja Obsługi

Strona 289

7-25

Unit 1

Interface

CNC

(Customer Supplied)

HPR PAC

Dry Cutting System

4

3

2

1

1

A

4

3

2

A

B

C

D

B

C

D

141030

CONTROL BOARD

1 2 3 4

S301

1

2

J300

3

4

3 2 1

4

J303A

J303B

CNC Interface Cable

J303A

S301

J303B

J300

CONTROL BOARD

141030

HPR PAC

Dry Cutting System

Unit 2

J303A

S301

J303B

J300

CONTROL BOARD

141030

HPR PAC

Dry Cutting System

Unit 3

J303A

J303B

S301

J300

141030

CONTROL BOARD

HPR PAC

Dry Cutting System

Unit 4

CNC Interface Cable

CNC Interface Cable

CNC Interface Cable

Serial ID

Dipswitch

Machine Motion

Jumper Block

Jumper Block

Machine Motion

Dipswitch

Serial ID

Jumper Block

Machine Motion

Dipswitch

Serial ID

Jumper Block

Machine Motion

Dipswitch

Serial ID

J104

2

1

J105

1 2

J104

1 2

1 2

J105

J104

1 2

1 2

J105

J104

1 2

1 2

J105

Notes:

1) For single system installations set Serial ID (S301), and Machine Motion (J300) as shown in Unit 1,

jumpers J104 and J105 must be closed.

2) On multi-system installations refer to the illustration.

Jumpers J104 and J105 are left open on all systems except for the very last system where

they are in the closed position.

Termination resistors (120-ohm) or termination jumpers must be installed/set at the CNC for

each of the RS-422 RX and TX signal pairs.

3) If a Hypertherm Automation Controller is being used, and there are intermittent communication

failures (PS Link Failure), try removing the jumpers on J104 and J105 on the control board, and the

termination jumper (J6 or J8) on the serial isolation board in the controler. Only remove

the termination jumper on the serial isolation board that is connected to the HPR

power supply. See sheet 19 for more details.

Optional Multi-System Interface

120

RX

Termination

Termination

120

TX

5 6 7 8

1

2

3

4

3 2 1

4

1

2

3

4

3 2 1

4

1

2

3

4

3 2 1

4

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

ELEC SCH:HPR400XD PWR SPLY W/AUTO

E

013374

SHEET 21 OF 24

S301

1 2 3 4 5 6 7 8

All switches are in the OFF position

Dipswitch setting example: As shipped

2

1

3 4

5 6

7 8

ON

ON